Sigatec

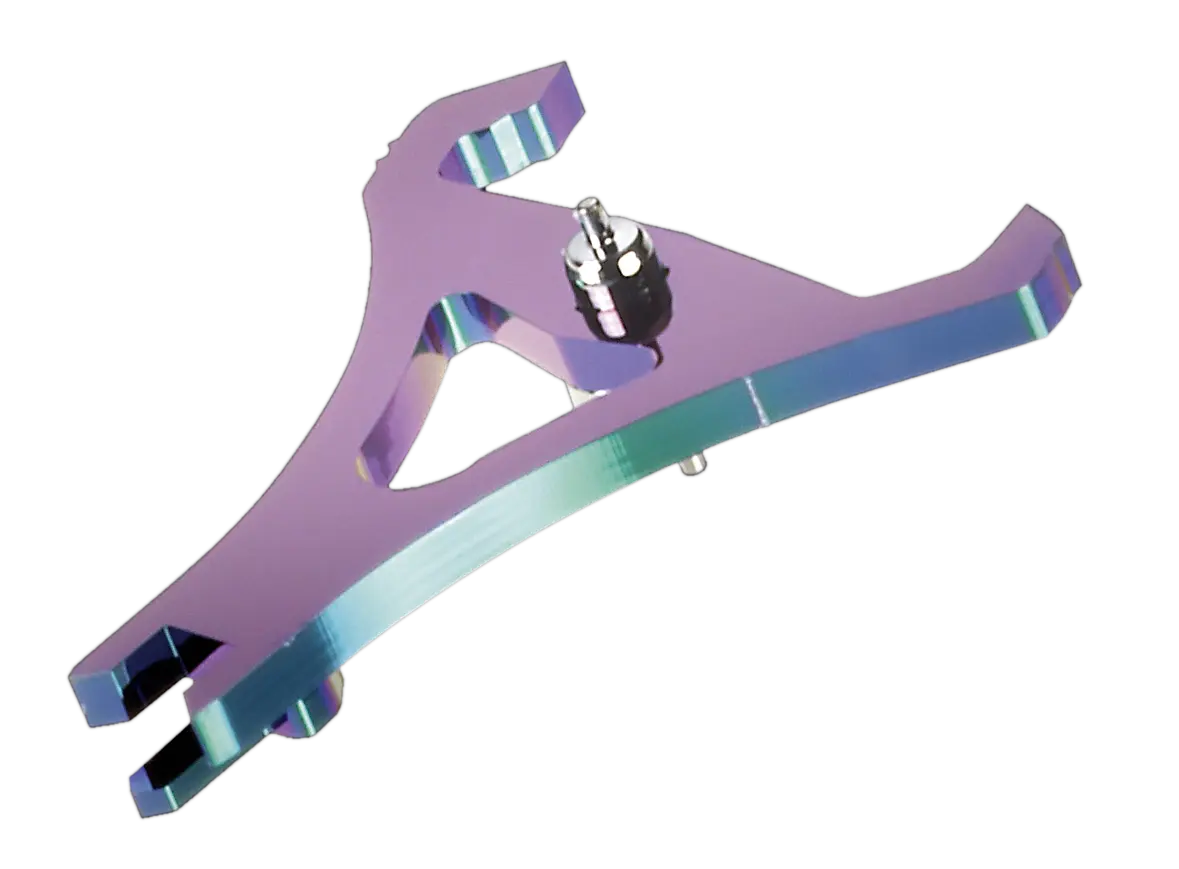

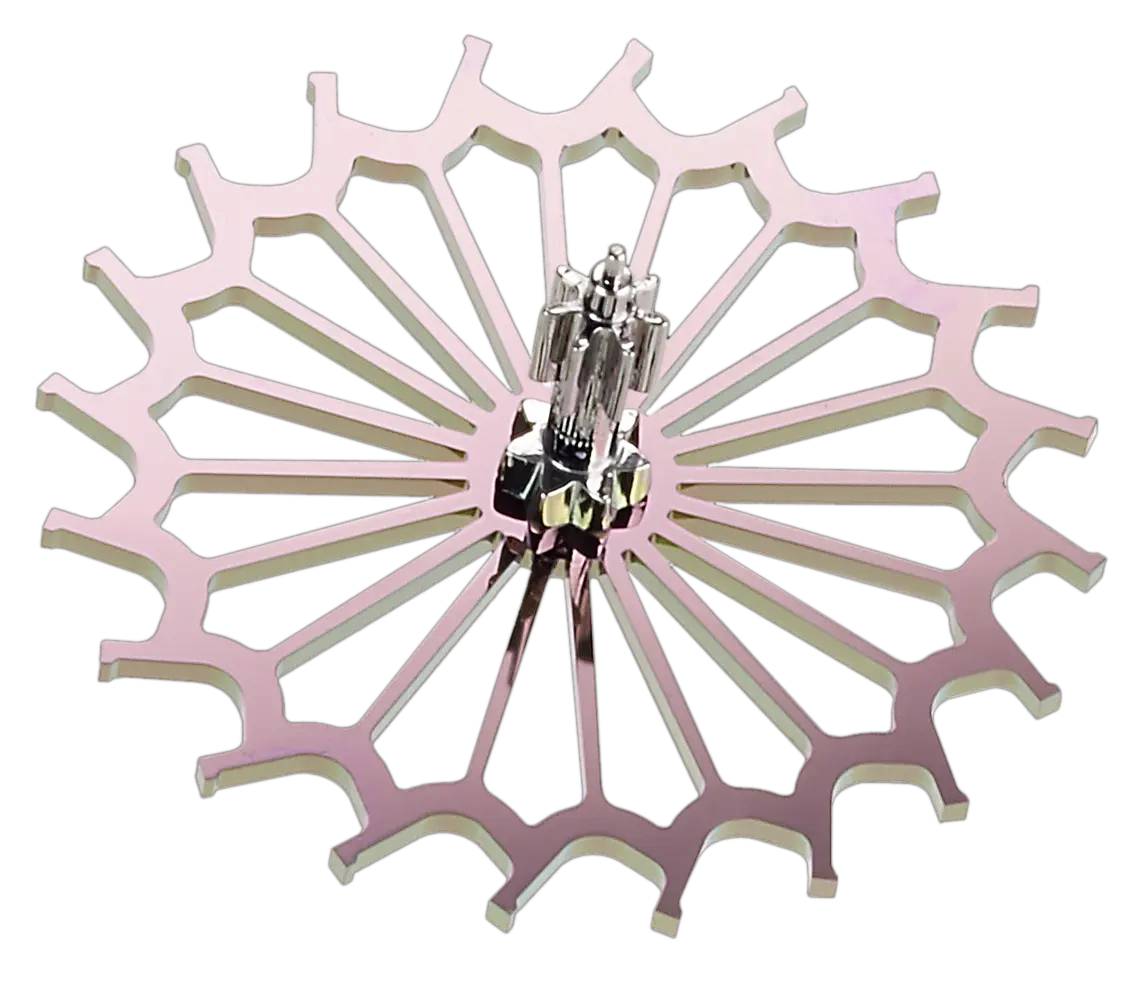

Founded in 2006 by Ulysse Nardin and Mimotec, Sigatec is a company specialized in the manufacture of micromechanical components in silicon. It produces parts for the watchmaking industry (escapement wheels, anchors, spiral springs, etc.), as well as for the aeronautical and biomedical industries.

The key activities are carried out in a clean room, in an extremely clean environment. The processes used by Sigatec are optimized for the realization of single parts as well as for large series.

The advantages of silicon are:

- Lightness

- Elasticity

- Hardness

- Non-magnetism

Competences

Manufacturing

Sigatec uses the “DRIE” (Deep Reactive Ion Etching) deep etching technology, which allows to produce parts with a precision close to the micron, as well as complex geometries difficult to achieve by conventional manufacturing means. The components can be produced on one or two crossed levels.

Assembly

Sigatec also offers final assembly of components (escapement wheel, anchor, oscillators etc..). In this way you will receive ready-to-use sub-assemblies. These operations are performed manually or automatically on our latest generation machines.

Markets served

- Watchmaking

- Biomedical

- Diffusion and filtering of products

- Connectivity

- Aviation

Technologies used

Manufacturing technology

- Deep etching – DRIE

Assembly technology

- Gluing

- Manual or automatic screwing

- Balance wheel and balance spring counting

- Geometrical controls of assembled parts

Surface technology

- Surface oxidation

- Diamond deposition

- Decorative or holographic engraving