Axial Medical

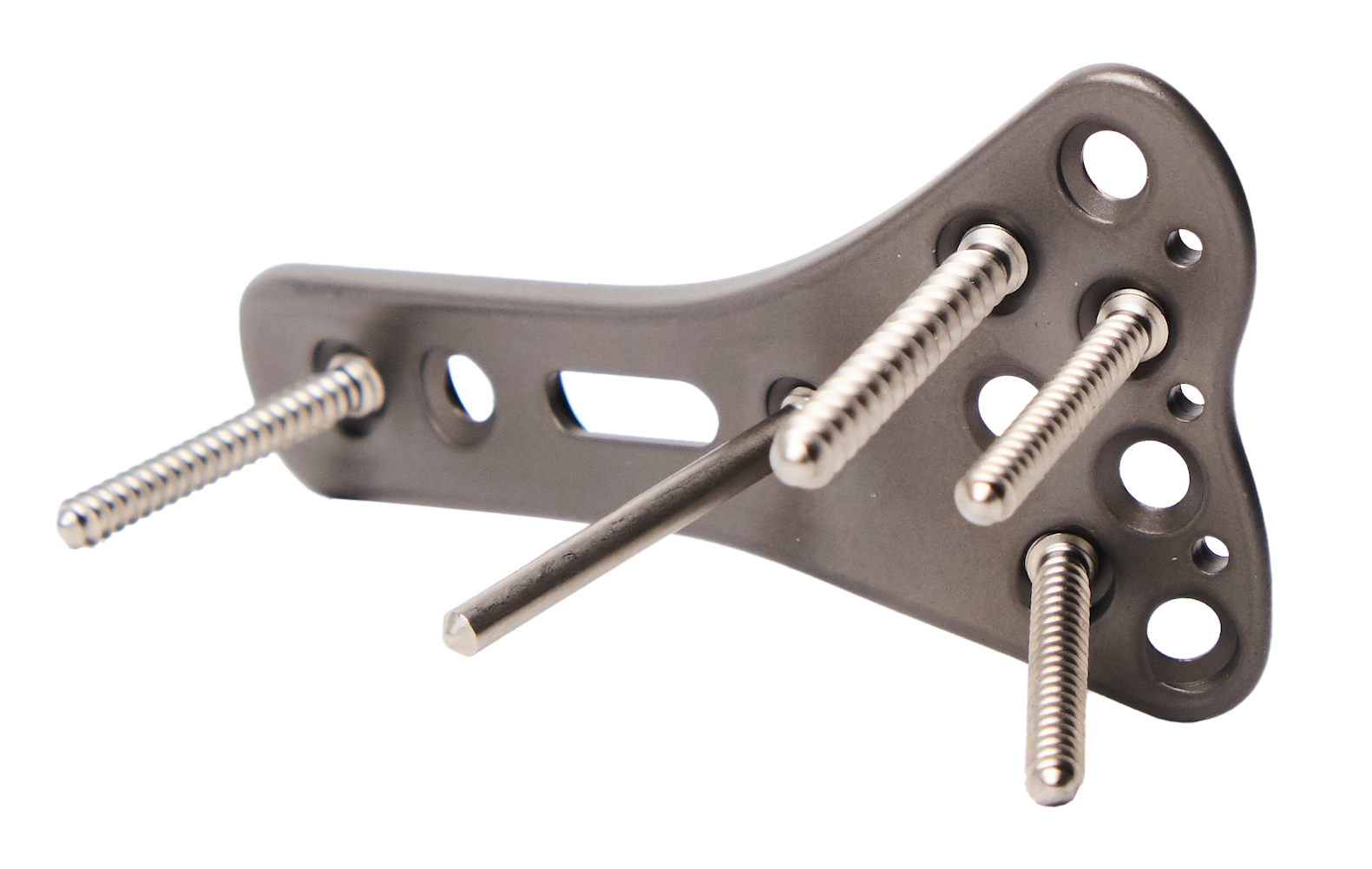

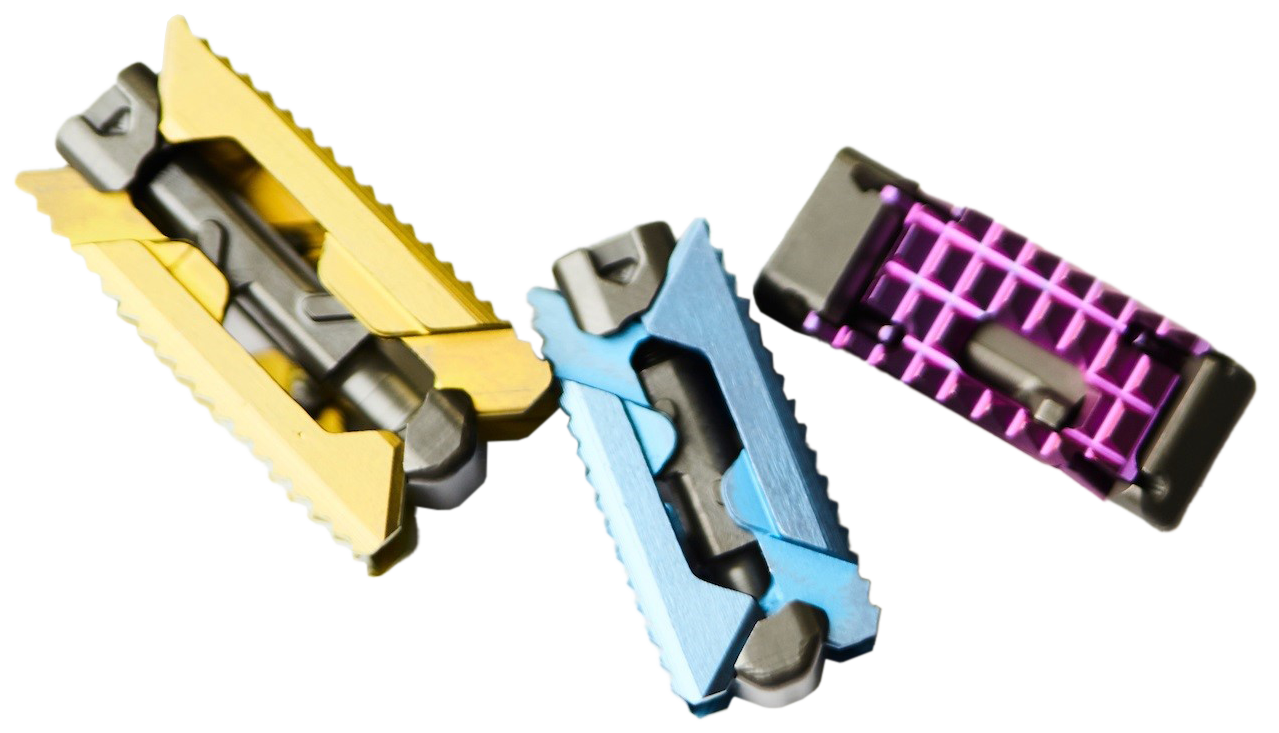

Located just outside of Philadelphia, Pennsylvania, Axial Medical operates a 4,000-square-meter facility with over 60 five-axis CNC machines, dedicated entirely to the production of medical devices. Axial’s vision is to be a world leader in Orthopaedic Medical Device manufacturing. The company is 100% focused on the production of complex implants for the spine, sports medicine, trauma, extremity and reconstructive markets. Its main products are expandable cages, anatomical bone plates, cannulated screws and other implants for the treatment of fractures and bone fixation.

Expertise

5-Axis Milling

Axial’s foundation was built upon a strong 5-axis milling background. With over 30 5-axis CNC spindles, Axial has enough capacity to handle the largest volume product launches. The team is incredibly talented and paired with their high-end equipment, they product the most complex anatomical trauma plates in the world.

Swiss Turning

Axial defies the conventional expectations of Swiss-style machining and pushes the boundaries of innovation to produce implants considered “impossible” to manufacture with Swiss turning. This drastically reduces costs and increases production throughput. Aside from their production innovations, they also produce hundreds of thousands of cannulated screws per year.

Wire EDM

Axial is known for its mastery in the production of expandable implants. To ensure that these implants function properly, tolerances are extremely tight – some of which would be impossible without wire EDM technology. They have multiple FANUC wire EDMs, all capable of maintaining single micron tolerances.

PEEK Machining

Their PEEK cell is fully enclosed and dedicated to PEEK production. They maximum yield programming and automated processes to ensure the lowest possible material costs for their customer. All PEEK material is stored in customer-specific, locked cabinets.

Quality

The company has a notoriously low rejection rate (less than 1%). To maintain this level of yield, they focus on accountability, best practices, and continuous improvement. To ensure that these implants meet customer specifications, Axial invests heavily in the latest metrology equipment and training.

Assembly & Finishing

To reduce costs and lead times for its customers, the company performs almost all post-processing in-house, including passivation, electropolish, laser marking and even anodizing of type 3 (color) and type 2 (gray hard coat) titanium.

Market served

Products & Services

- Spine

- Trauma

- Extremities

- Foot & Ankle

- Sports Medicine

- Orthopaedic Reconstructive

65 Richard Road, Warminster,

Pennsylvania 18974, USA

+1 267 961 2600

info@axial-medical.com

www.axial-medical.com