« LIGA » Springs

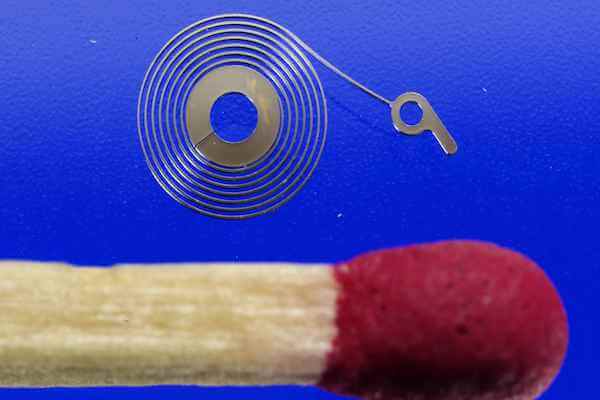

Watch movements contain a large number of springs with various different functions. These must meet the specific criteria in regards to: strength, rigidity, preloading, obstruction, case loading, etc.

It is equally essential that their dimensions are correct in order to ensure durability and accuracy of performance over time.

The introduction of a new electro formable material called LigaFLEX™, (a nickel alloy), enables the production of springs with high elastic properties by using the UV-LIGA technology.

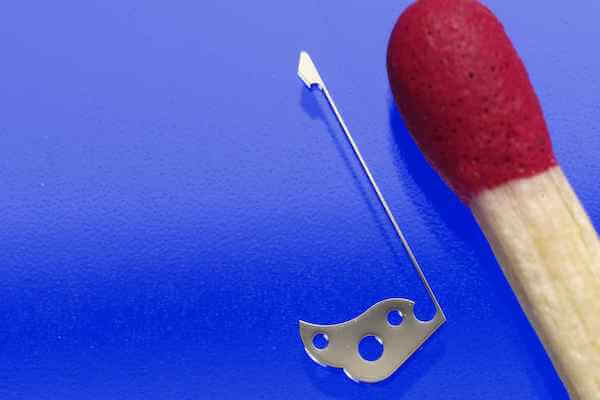

This procedure of manufacturing benefits from a large freedom of design and micrometric precision which guarantees the reliability of identical strength of all production batches as well as the factors of larger shapes (height/width).

Our manufacturing process enables us to produce fine blades ranging up to 50 microns with a margin of +/-3 microns.

The LigaFLEX™ benefits from an elastic limit of over 2000 MPa and a hardness of 610HV. This material complies absolutely with the International REACH standard.

For all requests you can contact Adrian Häubi at MIMOTEC, under the following address: