Horlyne

Horlyne has been developed at La Chaux-de-Fonds in tight connection with the high-end watchmaking industry, by meeting its quality and creativity requirements.

Over the years, the company has become a leader in the production of high-end oscillating weights by mastering the manufacturing process from A to Z, thanks to the integration of three trades that bring a precious character, an aesthetic that carries ancient know-how, and innovative ideas: guillochage, gem-setting and engraving.

Horlyne combines artisanal quality and extensive production capacities with all the flexibility provided by state-of-the-art technologies. The processes and procedures that structure its work are defined in consultation with each client, in a planned phase upstream. At Horlyne, you will find reliable contacts, an innovative impetus and multiple talents working towards the same goal: the added value of your product, its power of seduction, its competitiveness in the most demanding markets.

Process

The order – production – delivery process is unified and dynamized by an ERP software.

The production workshop, in interaction with its quality control structure and its R&D unit, has a set of equipment covering all its needs in CNC turning, milling and decoration.

Horlyne’s activities are part of a global and transparent process in which client companies actively participate.

Products and services

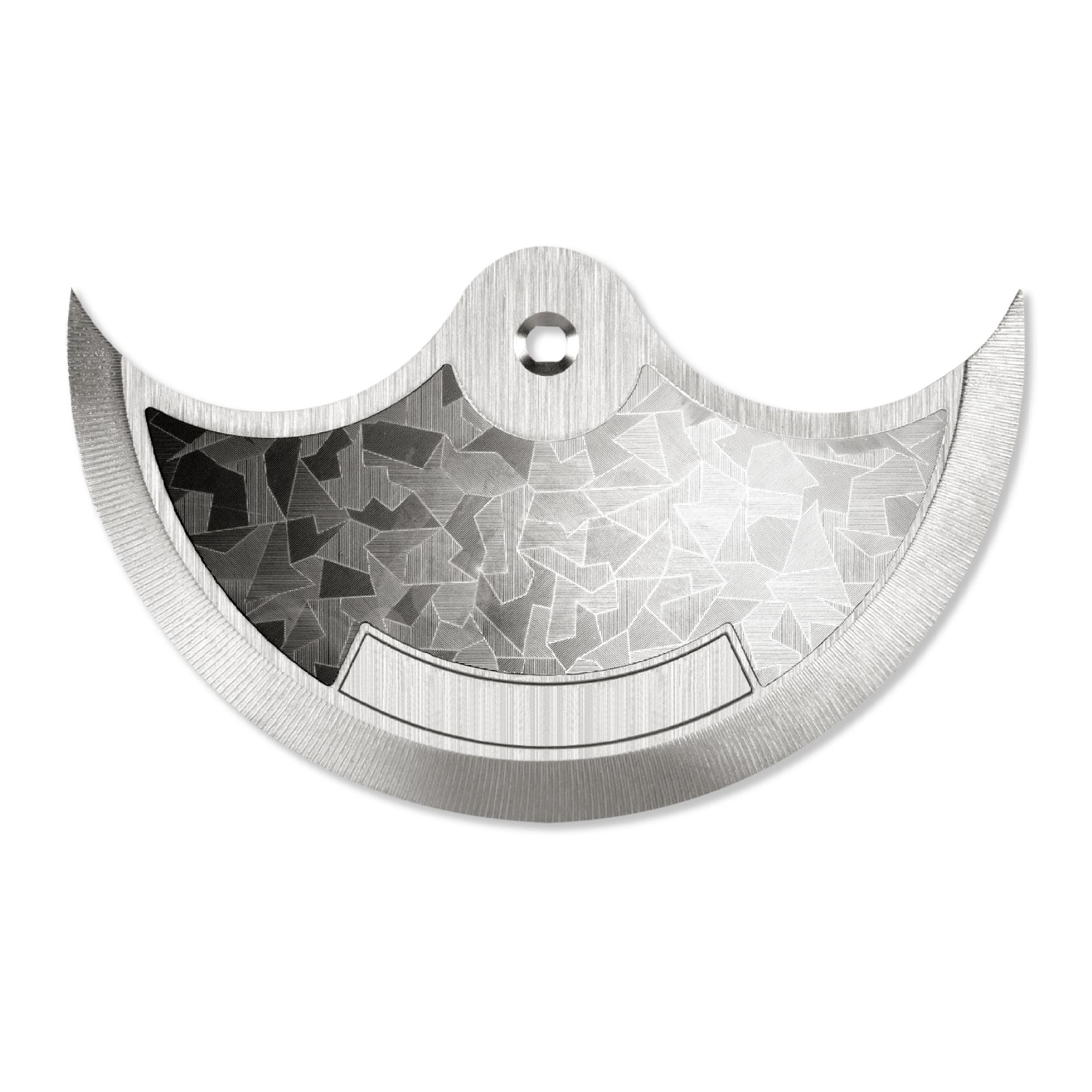

Oscillating weights: With the oscillating weights, the company’s flagship product, Horlyne gives the full measure of its means in terms of manufacturing, creativity and knowledge of the watchmaking market (demand, trends, power of innovation…).

Horlyne delivers the product on a turnkey basis and carries out all the decorations: stone-setting, guilloche, CNC engraving, Nano and Femto laser engraving, polishing, blocked. The materials worked are mainly gold, platinum, heavy metal (tungsten) and bi-metal.

Your request is followed up by a unique, responsive manager, who is always present right up to your assembly line.

Stone-setting: Horlyne sets diamonds and other colored stones in both round and baguette shapes in steel, precious metals and various contemporary materials.

Guillochage: The work consists in finely engraving networks of lines, curved and straight. Horlyne brings together precious know-how and latest-generation equipment: guilloche lathes, copying machines, “straight line” machines.

Horlyne also masters the technique of “CNC” guillochage, for a clientele interested in the beauty of a guilloché decoration at very competitive prices.

Horlyne’s creativity opens up a wide range of applications: guilloche work on oscillating weights, watch cases, movements, dials, etc.

All materials used in the high-end market are suitable for this work.

Engraving: Horlyne does all types of engraving for decoration (shapes, drawings, etc.) and identification (marks, numbering, various inscriptions). Its equipment allows it to engrave in hollow, in relief and by skeletonization.

Microengraving by CNC or by the latest-generation laser (Femto), mastered in its most delicate applications, lends itself to precise executions on very thin parts, such as cases, movements, dials, weights.

Market served

Products & Services

Rue du Collège 92

2300 La Chaux-de-Fonds, Switzerland

+41 (0)32 967 99 22

info@horlyne.ch

www.horlyne.ch