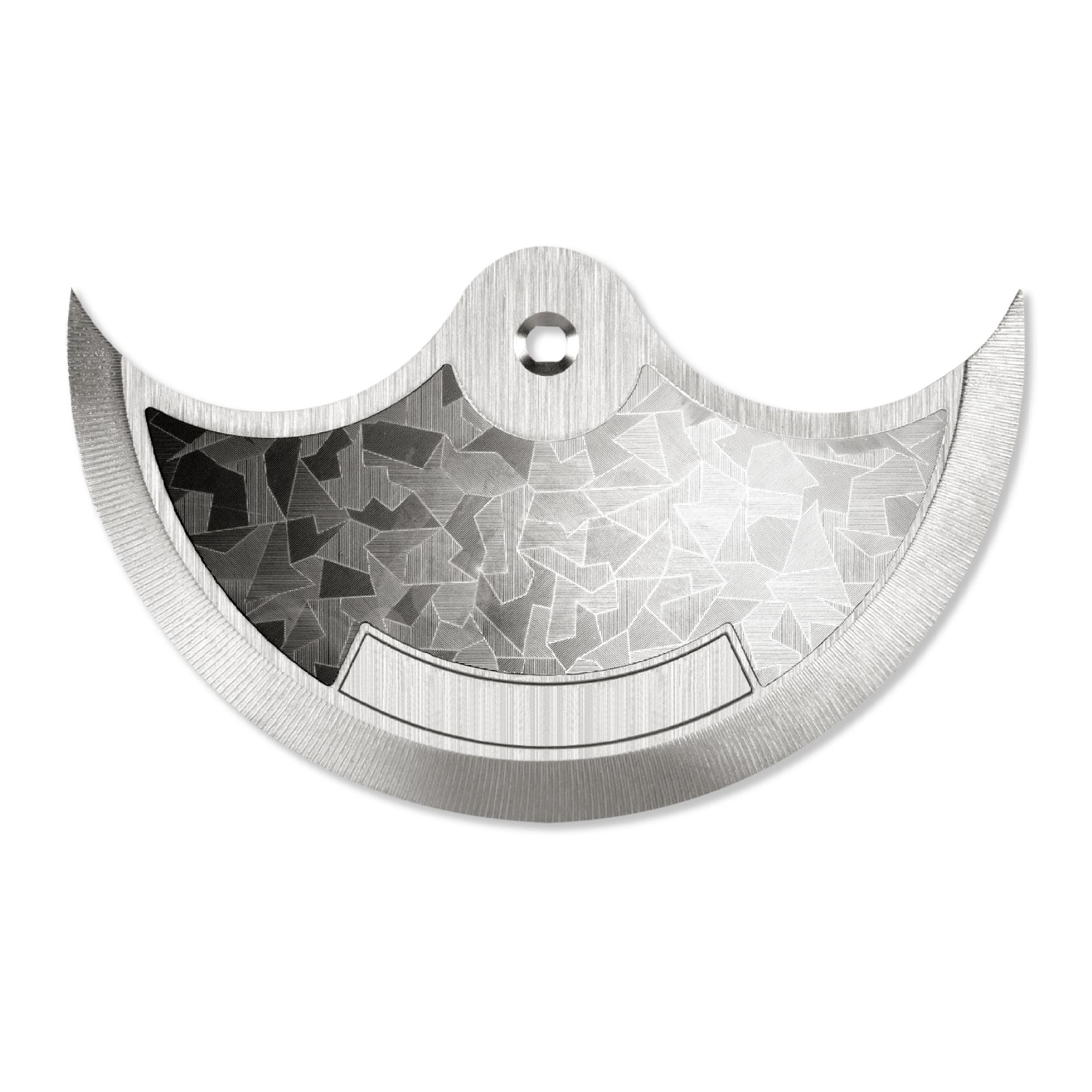

Oscillating Weights

A mechanical watch uses an oscillating weight to ensure its functionality. It is a component that rotates freely inside the watch which creates energy that is preserved by the spring barrel through kinetic energy (movements made by the watch-bearer). This enables the functioning of watch as long as it is being worn.

For the production of oscillating weights, washers with heavy metal, produced from tungsten powder pressed and poured into moulds of different diameters are used. Once heated in the furnace (or sintering), they are calibrated and reheated in the furnace so as to avoid any torsion within the materials. Acrotec’s production means are entirely automatic, which allows the company to be competitive from the prototype size to large-sized quantities. Flawless execution is ensured thanks to effective quality control in place. The oscillating weights produced can be labelled “Swiss Made” allowing for the complete satisfaction of the internationally renowned clients.

A wide range of more than 100 different models of oscillating weight has been created in response to customer demand, such as weight segments to be assembled with brass or titanium sheets, mono-block weights, etc. Acrotec carries out ébauche turning, milling, engraving and trimming, and also carries out decoration (snailing, Geneva stripes, graining, surface finishing, varnishing and pad printing). Assembly and riveting of bi-metallic balances are also possible.

For all requests you can contact Stéphane Grabalosa at DÉCOVI, under the following email :

With the oscillating weights, the company’s flagship product, Horlyne gives the full measure of its means in terms of manufacturing, creativity and knowledge of the watch market (demand, trends, power of innovation…).

Horlyne delivers the product on a turnkey basis and carries out all the decorations: setting, guilloche, CNC engraving, Nano and Femto laser engraving, polishing, blocking, sandblasting, côtes de Genève, colimalisation, etc.

The materials worked are mainly gold, platinum, heavy metal (tungsten) and bi-metal. Your request is followed up by a single, responsive manager, who is always present right up to your assembly line.

For all requests, you can contact Horlyne at the following email address :