Friedrich Daniels

Founded over 75 years ago, Friedrich Daniels is a fourth-generation family-owned company located in Solingen, Germany. With decades of experience, it has established itself as a globally renowned leader in the development and manufacturing of surgical instruments.

Approved by the FDA for both prototypes and production and certified to ISO 13485:2016 standards, Friedrich Daniels embodies excellence and innovation in the field of surgical instruments.

Expertise

Versatility is at the core of Friedrich Daniels’ expertise. The company excels in the manufacture of top-tier custom surgical instruments, offering comprehensive solutions that meet the most demanding needs. Friedrich Daniels’ areas of expertise encompass:

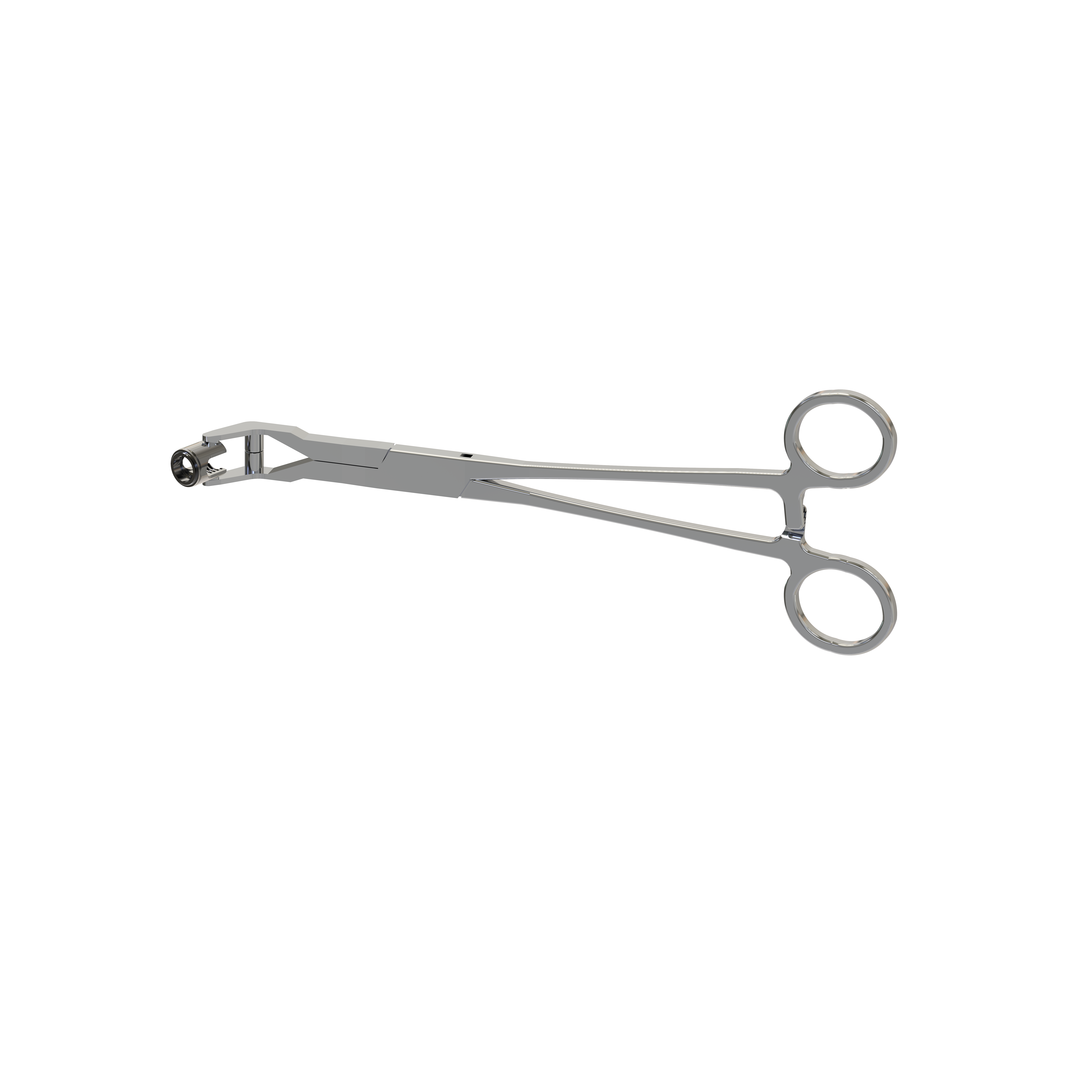

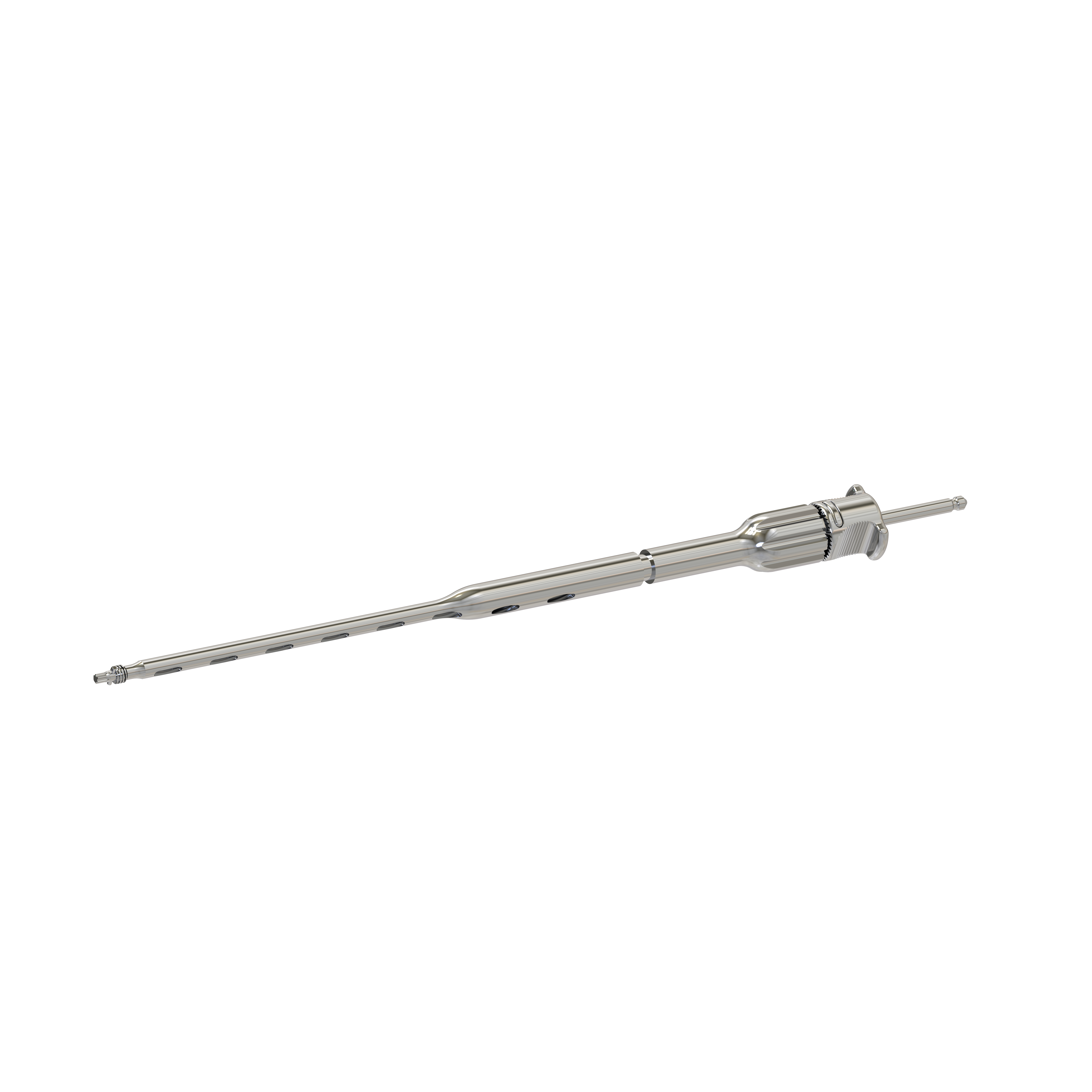

- Spinal Surgery: Friedrich Daniels offers a comprehensive range of systems for spinal surgery, covering anterior, posterior, lateral, and minimally invasive aspects. These systems are designed to enhance the precision and efficiency of surgical procedures.

- Navigation Systems: The company develops advanced navigation systems, including drills and taps, to assist surgeons in navigating with precision during complex procedures.

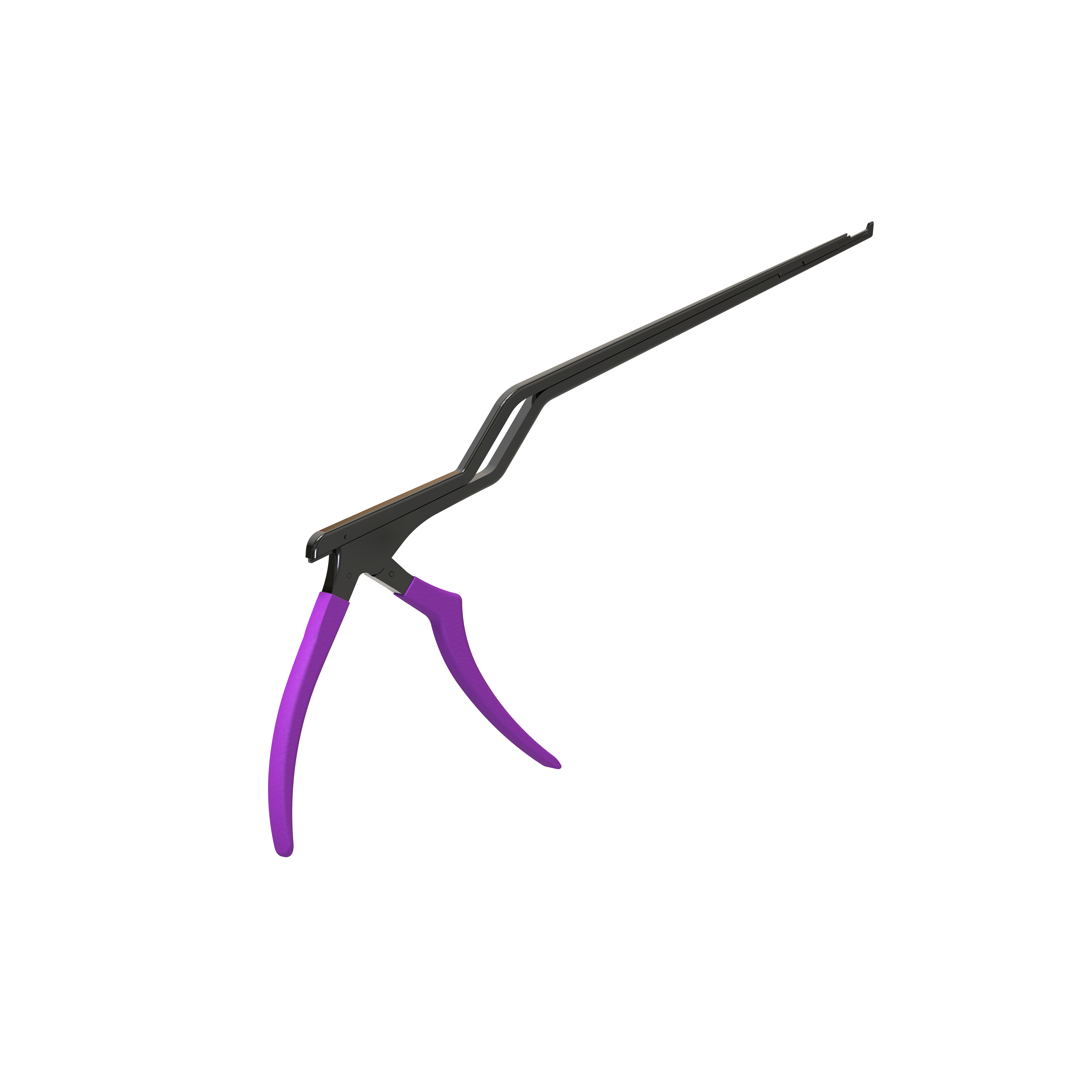

- Silicone Handle Design: Friedrich Daniels also places a strong emphasis on the ergonomics and comfort of surgical instruments by designing high-quality silicone handles for optimal handling.

- Foot & Ankle: The company provides innovative solutions for foot and ankle surgery, contributing to the improvement of patients’ quality of life.

- Traumatology: Friedrich Daniels excels in the manufacture of advanced traumatology instruments, crucial for the effective treatment of fractures and injuries.

Advanced production capabilites

Friedrich Daniels has a comprehensive set of advanced production capabilities, including:

- 3 to 5-Axis Milling: With 17 milling centers, the company is equipped to perform complex milling operations, ensuring unparalleled precision in instrument manufacturing.

- Turning: Friedrich Daniels has 10 turning centers, enabling the production of high-quality components for its instruments.

- Automation: Automation is at the heart of Friedrich Daniels’ production, ensuring increased efficiency and consistent quality.

- Waterjet Cutting: This cutting-edge technology is used for precision cutting of specific materials.

- Electrical Discharge Machining (EDM): Friedrich Daniels masters this technique for the production of complex-shaped parts with strict tolerances.

- Laser Marking: The company employs laser marking to ensure product traceability.

- Grinding: Friedrich Daniels ensures impeccable finishing of components through grinding.

- Cleaning: The company ensures that its products meet the strictest cleanliness standards.

Friedrich Daniels’ commitment to excellence, quality, and innovation makes it a trusted partner for healthcare professionals worldwide. With decades of experience and a constant pursuit of perfection, Friedrich Daniels is at the forefront of manufacturing high-quality surgical instruments.

Market served

Product & services

- 17x Milling 3 to 5-axis

- 10x Swiss/Turning Centers

- 3x Automatisation

- 1x Waterjet

- 11x Wire/Sink EDM

- 3x Lasermarking

- Drill-/Cylindrical- Grinding

- Cleaning

Dönhoffstr. 6,

42655 Solingen, Germany

+49 212 810050

info@friedrich-daniels.com

www.friedrich-daniels.com